Coborn RG5B-XD

Semi-Automatic Grinding Machine for PCD, PcBN

& Carbide Tools

Coborn’s RG5B-XD is a very rigid machine, purpose designed for grinding the latest, super-hard tool materials. Tool formats possible include:

- PCD & PcBN tipped turning/milling inserts and shank type tools

- PCD & PcBN multiple flank and multiple radii tools such as grooving tools

- Tools with multiple clearance angles

- PCD tools such as end mills, reamers and multi-tooth saws with optional rotary fixture

Wheel speed, wheel direction, stroke position and stroke amplitude can be set from the touch-screen. These tool blocks can be stored as a tool program for later recall or modification from the in-built industrial PC.

The machine may be fitted with an optical projector or the enclosed VS5-G vision system (as shown).

In-process measurements are possible with the additional VS5-GM vision system measurement module.

Main Options & Brief Spec

Main Options

- Variable speed inverter drive wheel head

- Digital pivot angle display

- Rotary fixtures – CF10 or CF14

- Central lubrication system

- Pneumatic pivot lock

- Hand wheel – fine traverse adjustment

- Air blast tool drying

- Audio touch probe

- Metric or imperial

- Automatic Pivot (RG5C)

Brief Specification

Wheel head

| Grinding motor | 2.2 kW |

| Oscilation | 300mm max |

| Traverse speed | 0.1 – 50mm/sec |

| Acceleration | Programmable |

| Wheel format | Vitrified bond, 6A2 |

| In-feed travel | 35mm |

Controls

| Steps per tool | 25 max |

| CNC Controller | Industrial PC |

| Back up | via Ethernet or USB port |

| X Y read outs | 1 μm |

Work range

| Cross-slide travel | 40mm |

| Maximum radius | 35mm |

| Conical clearance | 0-25 degrees |

| Cylindrical clearance | 0-25 degrees |

| Pivot motion | 200 degrees |

Strengths

- Extremely rigid construction, designed for PCD tool manufacture. Enhanced working envelope size

- Touch-screen control program blocks

- 25 memories for stroke start positions and stroke lengths, programmed reciprocation amplitude with digital position readout

- One touch, automatic view facility without loss of position

- 1 micron wheel infeed resolution

- Conical clearance movement up to 25 degrees. Via a single hand-wheel

- Tool radius up to 35mm

- Adjustable grinding pressure

- Fully compatible with Coborn fixtures

- Can be fitted with a projector or camera /monitor system/ vision system (VS5)

- Vision system with measurement module (VSS-M) available

- Rotary fixtures, tool nest/holders available

- Can be supplied with or retro-fitted with Automatic Pivot (RG5C)

Control System Features

- Control via an industrial PC, software by Coborn Engineering

- Easy to control, no ‘computing’ know-how necessary

- Input via a large, easy-to-read 15” touch-screen

- Tool programs quickly and easily developed ensuring minimal setup time

- Reciprocation amplitude and position stored and adjustable to 1 micron

- Reciprocating speed stored and adjustable from 0.1 to 50mm per sec

- Automatic view position facility, allows one-touch viewing and return

- Digital readout with one micron resolution, switchable from mm to inches

- Control unit is mounted on double swivel and tilt arm for convenient positioning

- Remote diagnosis over internet

- Network to central tool file repository

Technical Details

| Characteristic | Details |

|---|---|

| MACHINE | |

| – Machine type | Manual PCD Grinding Machine |

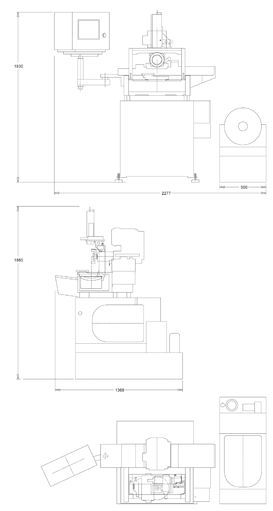

| – Dimensions – main machine (w x d x h) | 1,400mm x 1,270mm x 1,860mm |

| – Total machine weight | 7700kg |

| CONTROL SYSTEM | |

| – Industrial PC + touch screen | Yes |

| – Blocks per tool program | 25 maximum |

| – Block records – wheel speed – wheel direction – wheel position – wheel stroke amplitude |

Yes Yes Yes Yes |

| – Internet connection | Via ethernet port |

| – Software upgrades, maintenance via Internet | Yes |

| OPTICS | |

| – Options available | Microscope / Projector / VS5G / VS5G + M |

| – Optics adjustment | X & Y slides = 30mm; Z slide (focus) = 50mm |

| WHEEL SPINDLE | |

| – Spindle type | Coborn precision, dynamically balanced |

| – Wheel spindle drive power | 2.2kW |

| – Speed range (if no inverter supplied) | Hihg speed – 4,000rpm, Low speed – 2,000rpm |

| WHEEL IN-FEED | |

| – By hand wheel | Yes |

| – In-feed travel available | 45mm |

| – In-feed travel resolution | 1µm (via Renshaw encoder) |

| – Typical roughing in-feed rate on PCD | 12 – 15µm/sec |

| – Typical finishing in-feed rate on PCD | 3 – 5µm/sec |

| – Grinding pressure adjustment | 90 Newtons minimum to be ‘locked’ |

| WHEEL STROKE | |

| – Maximum stroke length | 300mm |

| – Wheel stroke frequency | 0 – 100 Hz (typicaly used at 25Hz) |

| WHEEL STROKE POSITION | |

| – By hand wheel | Yes |

| – Wheel stroke position adjustment | Repeatability 10µm |

| WORK TABLE – ‘BOOM’ | |

| – Manually adjusted via one hand wheel | Yes |

| – Inclination (for conical clearance) | 0 – 25 degrees |

| CROSS SLIDE | |

| – Clamping surface size | 260 x 130mm |

| – Cross table travel range | 30mm |

| – Cross table position resolution | 10µm via vernier scale on handles |

| PIVOT | |

| – Pivot motion | Manual |

| – Pivot movement | 200 degrees |

| – Pivot setting | via vernier stops (4 available) |

| – Pivot position acuracy | +/- 1 minute of arc (readout on touch scren) |

| – Maximum tool radius | 0 – 35mm (40mm possible) |

| TOOL POST | |

| – Tool post hand | Righ hand fitted as standard |

| – Tool nest format | Square fitted as standard |

| – Tool nest height adjustment | Yes |

| – Tool nest tilt (cylindrical clearance} | ± 20 degrees |

| GRINDING WHEELS | |

| – Wheels bond type recommended | Vitrified bond |

| – Format | Usually 6A2 |

| – Wheel grit size for roughing PCD | Typically D25 – D35 |

| – Wheel grit size for finishing PCD | Typically D5 – D10 |

| – Wheel arbor | Required; allows rapid wheel changes |

| DRESSING | |

| – Method | By dressing stick |

| – Stick recommended | Aluminium Oxide, 20mm x 20mm, 400# |

| LUBRICATION | |

| – By hand pump to nipples | Yes |

| COOLANT UNIT | |

| – Coolant unit dimensions (w x d x h) | 1,150mm x 500mm x 670mm |

| – Coolant unit weight | 118kg |

| – Coolant pump power | 0.12kW |

| – Coolant tank capacity | 100 litres |

| – Coolant ump flow rate | 50 l/min |

| ELECTRICAL REQUIREMENTS | |

| – Electrical Requirements | 3 phase, 415v or 220v |

| OPTIONAL EXTRAS – NOT A COMPLETE LISTING | |

|---|---|

| 1. Inverter for wheel spindle speed control | Available |

| 2. CF10 Coning & Indexing Fixture – Face plate for adapters – Maximum diameter – Maximum tool length |

Yes – further information available 90mm for HSK, ISO,MK, Hydraulic chucks etc. 150mm 160mm from face plate |

| 3. CF14 Coning & Indexing Fixture – Face plate for adapters – Maximum diameter – Maximum tool length |

Yes – further information available 105mm for HSK, ISO,MK, Hydraulic chucks etc. 220mm 160mm from face plate |

| 4. KF2 – ‘K’ land attachment – For creation of K lands on PcBN tipped inserts |

Available |

| 5. Centralised lubrication | Available |

| 6. Tool nests | Many types available; tilting, round, square, V etc. |

| 7. Left hand tool post | Available |

| 8. AD1 – Digital pivot angle read-out | Available |

| 9. Auto tool air-blast | Available |

| 10. Grinding wheels | Available |

| 11. Wheel arbors | Available |