Coborn BM Series

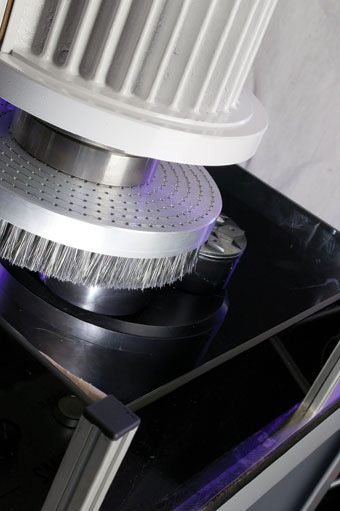

Coborn’s BM2B brushing machine is designed to remove the extreme sharpness from the ground edges of PcBN and PCD tipped inserts and tools.

Grinding scratches can result in stress raisers and lead to premature edge cracks. Edge brushing removes these scratches and gives a tougher, more stable tool edge and thus a longer tool life.

All PcBN tools should be edge brushed before use as this improves tool life by a factor of 2 or 3 times.

The BM2B brushing machine key characteristics are:

- 3 station machine

- Economy motor

The brush used is made with a natural bristle which provides excellent durability. Fine micron diamond powder, typically 4-6μm particle size, is mixed with ‘tallow’ (a natural animal fat) or other suitable synthetic grease. This paste is applied to the brush.

The inserts are held on the work table in carrier plates (shrouds) with suitably shaped cut-outs.

The brushing process and brush rotation direction are controlled by programmable timers so that consistent results can be obtained.

The Machine In Use

Typically, up to 100 inserts can be brushed in one operation on a 3 station, BM2 machine. The complex, planetary motion of the insert holding ‘pods’ combined with the motion of the brush produces a uniform edge hone. The depth of the hone radius is controlled by adjusting the brushing height (pressure) relative to the top surface of the inserts. The width of the hone is controlled by adjusting the brushing time.

Technical Details

| Characteristic | BM2B |

| MACHINE | |

| – Machine type | 3 station brushing machine |

| – Total machine weight | 237kg |

| – Number of stations | 3 |

| BRUSHING DRIVE | |

| – Type | Motor |

| – Speed range | 1000 rpm (max) |

| – Power | 0.55kW |

| – Brushing direction | Reversible |

| – Brushing direction programmable | 0 – 30 secs |

| – Brushing pressure | Adjustable |

| – Insert carrier table rotation | Yes |

| – Insert carrier rotation speed | 1 – 6 rpm |

| – Individual carrier rotation | Yes |

| TIMERS | |

| – Timer setting range | 1 minute – 100 hours |

| – Typical cycle time (on PcBN inserts) | 1 minute |

| BRUSH | |

| – Brush type | Natural bristle |

| – Brush body | Aluminium |

| CARRIER PLATES | |

| – Thickness | 2.5mm as standard |

| – Carrier material | Steel |

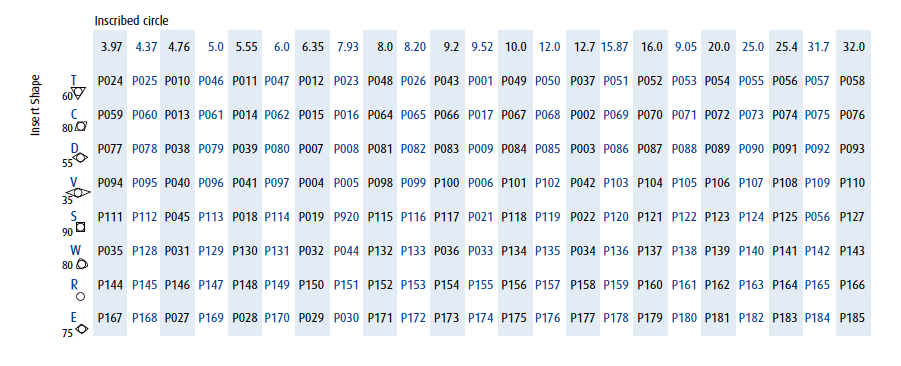

| – Formats available | Most ISO insert formats |

| ELECTRICAL REQUIREMENTS | 220/240v single phase |