Coborn PG Series

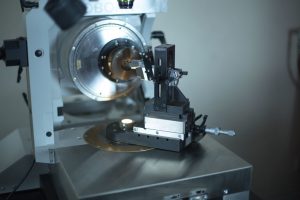

Planetary Grinding Machines for Single Crystal Diamond

Coborn make a range of machines for grinding single crystal diamond, the PG2, PG3+ and PG3B. The choice of machine depends on the application and the level of accuracy required.

The planetary motion allows the grinding direction to be changed so that the ‘soft’ directions of the diamond can be found. The planetary motion can be continuous or moved step-wise (jogged) in either direction.

To protect the wheel and tool, feed is achieved by a dead weight system.

A rotary fixture is available with indexing and continuous rotation for facets and cones.

PG3B

The PG3B has air bearings for both the pivot and the water cooled wheel spindle. The machine is designed for making:

• Low or controlled waviness, radius tools

• Multiple facet tools, conical tools

The pivot motion is automatic and controlled via a touchscreen. Pivot angle limits, dwell time at end of stroke and pivot speed can all be pre-set.

If ‘hard’ spots exist on the diamond then temporary pivot limits can be selected whilst running.

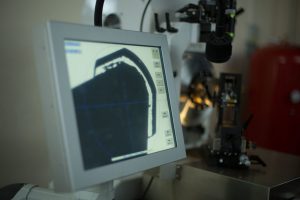

Tools are inspected via a VS5G vision system.

PG3+

The PG3+ has high precision angular contact bearings in both the pivot and HF Wheel spindle.

The machine is designed for making Radius and multi-facet tools.

Like the PG3B it uses the same Synthetic Granite base.

It can be fitted with optional Automatic pivot.

Ultra-high precision, CNC grinding machine for single crystal diamond tool manufacture. The new PG6 enables the automated production of ultrahigh precision diamond tools.

Brief Specification - PG3B

Main motions

| Wheel spindle | Air bearing |

| Speed | 0 – 12,000 rpm |

| Spindle direction | Clockwise and Anti-clockwise |

| Spindle tilt | 0 – 20 degrees |

| Stroke length | 0 – 28mm |

| Pivot spindle | Air bearing |

| Pivot range | 182 degrees (+/-91 deg) |

| Planetary motion | Continuous/jog |

| Planetary direction | Clockwise and Anti-clockwise |

Work range

| Maximum radius | 75 mm |

| Conical clearance | 0-20 degrees |

| Cylindrical clearance | 0-20 degrees |

Main Options

- Rotary fixture – CF13

- Metal bond or cast iron laps

Features

- Main controls sited off the machine to minimize transmitted vibrations

- Automatic pivot motion

- Variable lapping load 0.5 – 3 kg

- Precision ‘place’ and ‘lift’ mechanism

- Tool inspection by vision system

- In-feed precision 0.1 μm

- Digital pivot angle display

- Synthetic granite base

- Metric or imperial versions

- Remote diagnosis over internet

Optics

The PG3B machines are supplied with the VS5-G vision system which has a x60 – x600 zoom lens.

Technical Details

| Characteristic | PG3+ | PG3B |

|---|---|---|

| MACHINE | ||

| – Dimensions (w x d x h) | 900mm x 800mm x 1,800mm | 900mm x 800mm x 1,800mm |

| – Total machine weight | 800kg | 830kg |

| MACHINE CONTROL | ||

| – Machine control via | Separate control box | Separate control box and touch screen |

| – Memories | None | Last stored position |

| – Storage | None | Industrial PC |

| – Control box dimensions | 600mm x 600mm x 1200mm | 600mm x 600mm x 1,200mm |

| WHEEL SPINDLE | ||

| – Wheel spindle type | High frequency | High frequency |

| – Wheel bearings | High precision | Air-cartridge type |

| – Wheel spped range (via inverter) | 0 – 12,000 rpm | 0 – 12,000 rpm |

| – Wheel spindle tilt (conical clearance) | 0 to +20° | 0 to +20° |

| – Oscillation of wheel spindle | Yes | Yes |

| – Maximum stroke length | 28mm | 28mm |

| – Wheel position adjustment range | 0 – 100mm | 0 – 100mm |

| – Oscillation frequency (via inverter drive) | 0 – 32 strokes/min | 0 – 32 strokes/min |

| – HF spindle cooling system | Not applicable | Recirculating treated water |

| – Spindle nose taper | 12 degrees | 12 degrees |

| WHEEL SPINDLE COOLANT UNIT | ||

| – Pump capacity | Not applicable | 100 litres |

| – Motor power | Not applicable | 0.14kW |

| – Coolant unit dimensions (w x d x h) | Not applicable | 700mm x 620mm x 450mm |

| – Coolant unit weight | Not applicable | 20kg – dry weight |

| PLANETARY MOTION | ||

| – Wheel planetary motion | Yes | Yes |

| – Jog (clockwise and counter-clockwise) | Yes | Yes |

| – Continuous (clockwise and counter-clockwise) | Yes | Yes |

| – Lock in position | Yes | Yes |

| IN-FEED | ||

| – Load application | via dead weight | via dead weight |

| – Weights provided | 0.5kg – 3kg (0.5kg steps) | 0.5kg – 3kg (0.5kg steps) |

| – In-feed table travel length | 25mm | 25mm |

| – In-feed table resolution | 0.1 microns with optical scale | 0.1 microns |

| CROSS TABLE FIXTURE | ||

| – Travel length | 12mm | 12mm |

| – Tool height adjustment (‘K’ axis) | 85mm | 85mm |

| PIVOT DETAILS | ||

| Movement (‘C’ axis) | 182 degrees (+/- 91 deg) | 182 degrees (+/- 91 deg) |

| Resolution (using vernier scales) | 0.003 degrees | |

| – Digital readout | via AD2 (optional extra) | view on touch screen |

| – High resolution digital readout (optional extra) | Not available | 0.001 degrees |

| Pivot bearings | High precision | Air-cartridge type |

| Pivot motion | Manual/Automatic option available | Automatic |

| Radius maximum | 75mm | 75mm |

| Larger radii | with special arrangement | with special arrangement |

| – Hard spot arc focus facility | No | Yes |

| TOOL CLEARANCE FORMATS | ||

| – Cylindrical (via tool holder tilt) | Yes (+/-20°) | Yes (+/-20°) |

| – Conical (via wheel spindle tilt) | Yes (0-20°) | Yes (0-20°) |

| OPTICS | ||

| – Options available (not included) | Microscope OR projector OR VS5-G vision system | VS5-G camera vision system recommended |

| – Projection light source | Yes | Yes |

| – Optics mount movement (X – Y) | 12/12mm | 12/12mm |

| Magnification (microscope & projection) | x30 or x50 | x30 or x50 |

| Magnification (VS5-G vision system) | Zoom x60 – x400 | Zoom x60 – x400 |

| WHEELS | ||

| – Grinding wheel recommended | “SAM” metal bond | “SAM” metal bond |

| – Roughing grade | 1000# (typical) | 1000# (typical) |

| – Finishing grade | 2000# (typical) | 2000# (typical) |

| – Super-finishing grade | Cast iron lap or 5000# | Cast iron lap or 5000# |

| – Grinding wheel adaptor/hub | Required | Required |

| – Adaptor bore taper | 12 degrees | 12 degrees |

| ELECTRICAL REQUIREMENTS | Single phase 220v; 5.6 amp | Single phase 220v; 5.6 amp |